一、lamp accessories classification and material selection

Structural fitting

Lamp holder (base) : metal (aluminum alloy, zinc alloy), plastic (ABS, PC), ceramic, stone, etc.

Lamp arm/bracket: metal (steel pipe, aluminum pipe), plastic, wood.

Lampshade: plastic, metal, glass, fabric, acrylic, paper, etc.

Functional accessory

Light source: LED lamp bead, bulb (E27/E14 interface).

Circuit components: wires, switches, dimmers, power adapters.

Connecting parts: screws, fasteners, shafts, springs, etc.

二、 the core production process

1. Metal accessories production (taking lamp holder/bracket as an example)

Process steps:

Mold design: According to the drawing design mold (die casting mold, stamping die).

Material cutting: Cutting sheet metal/pipe using laser cutting, CNC cutting or punching press.

Molding process:

Die casting: Molten metal injection mold, suitable for complex shapes (e.g. zinc alloy lamp holder).

Stamping: Sheet metal by die stamping forming, suitable for simple structure.

Pipe bending/bending: Use a pipe bending machine to shape the metal pipe (lamp arm).

Surface treatment:

Polishing/sandblasting: Remove burrs and improve surface finish.

Electroplating (chromium plating, nickel plating) or anodizing (aluminum) : rust resistant, beautiful.

Spray (spray paint, paint) : custom color.

2. Production of plastic accessories (taking lampshade/base as an example)

Process steps:

Injection molding:

Plastic particles melt after heating into the mold, cooling molding, suitable for mass production.

Material: ABS, PC, acrylic, etc.

3D printing: Small batches or complex structures can be photocured (SLA) or fused deposition (FDM) technology.

Surface treatment:

UV coating: anti-scratch, increase luster.

Screen/thermal transfer: pattern printing.

3. Lampshade production (different material processes)

Metal/Acrylic lamp shade:

Laser cutting → Bending → Welding/riveting → Surface treatment (e.g. wire drawing, spraying).

Cloth/paper lampshade:

Cut → Sew/glue → Frame fixing (metal or plastic frame).

Glass lamp shade:

Blowing (traditional process) or die pressing → annealing → edging polishing.

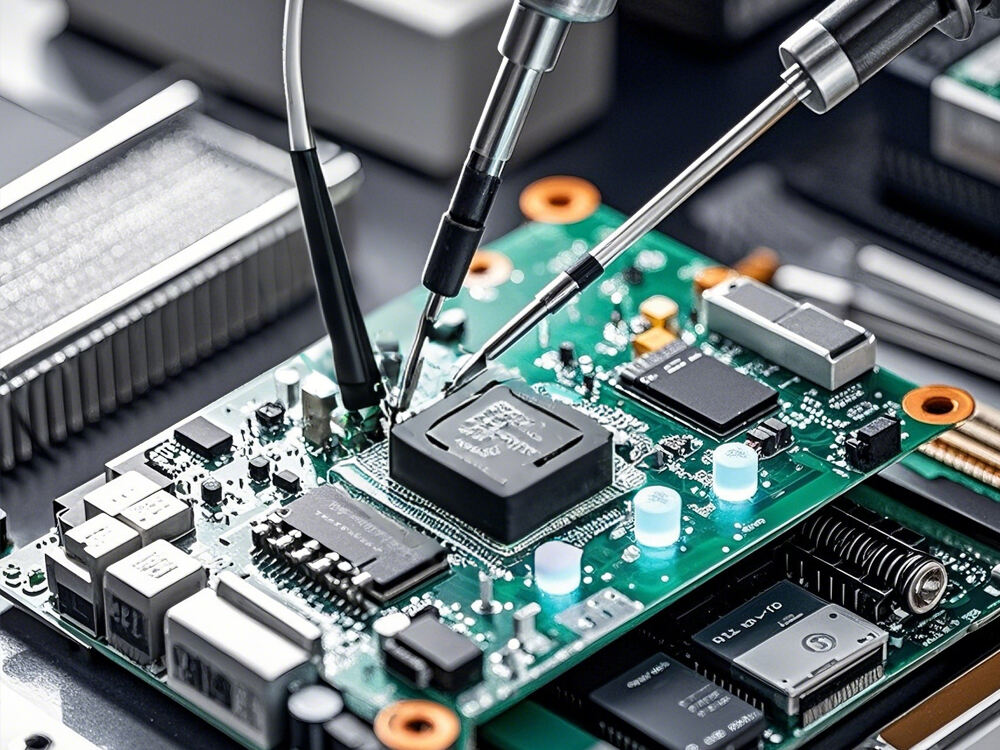

4. Circuit component assembly

Key steps:

Wire cutting: Cut and strip wire to length.

Welding: Connect the lamp holder, switch and dimmer module.

Insulation treatment: heat shrink tube or electrical tape wrapped solder joints.

Test: Use a multimeter to detect short circuit and open circuit.

5. Final assembly and test

Mechanical assembly:

Fasten the lamp holder, bracket, and lampshade by screws, snaps, or glue.

Install a light source (such as an LED module or bulb).

Functional test:

Switching sensitivity, dimming function, stability.

Safety test: insulation, temperature rise test (whether it is overheated for a long time).

三、 the key process technology

Mold accuracy: directly affect the size consistency of the parts (tolerance ±0.1mm).

Surface treatment: Determine the appearance of the texture and durability (such as electroplating to pass the salt spray test).

Automatic production: injection molding machine, mechanical arm assembly to improve efficiency.

Environmental requirements: RoHS certification (limit harmful substances), waste materials recycling.

四、 common problems and solutions

Metal burrs: Add deburring process (vibration grinding or manual grinding).

Plastic shrinkage: Optimize injection molding parameters (temperature, pressure, cooling time).

Circuit short circuit: strictly detect the insulation layer and welding points.

五、Development Trend

Lightweight design: aluminum alloy or carbon fiber composite material.

Intelligent integration: Add wireless control (Wi-Fi/ Bluetooth), touch sensing.

Environmentally friendly materials: biodegradable plastics, bamboo and wood instead of traditional plastics.